Since 2007,

one company has stood out for its unique approach

to branded e-commerce packaging -

Salazar Packaging.

- Project managers, no salespeople.

- Affordable custom packaging solutions.

- Sustainable, minimalist, intentional design.

- State of the art printing capabilities.

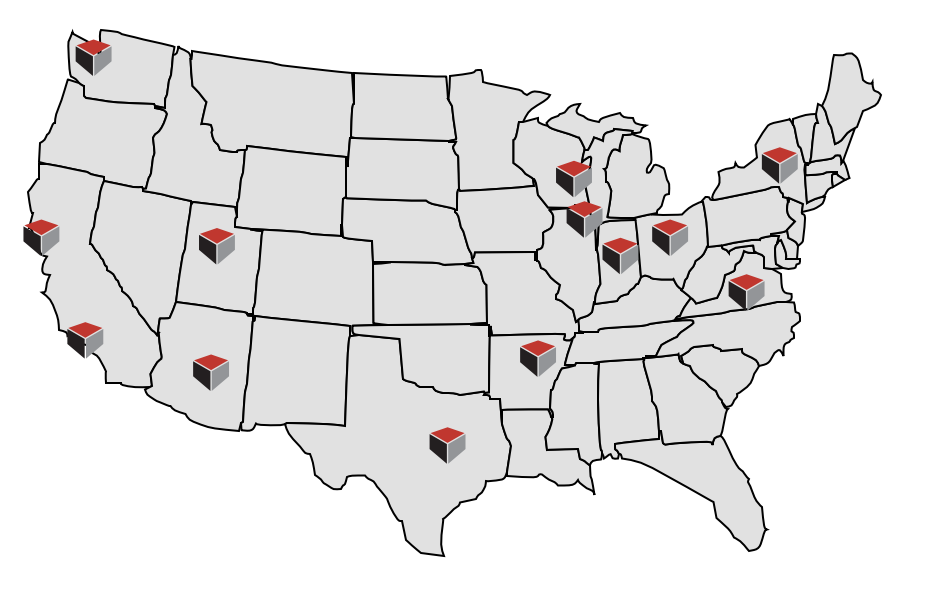

SERVING START-UPS AND E-COMMERCE BRANDS NATIONWIDE

Products / Services / Solutions

Working With Us Is Easy!

Contact us to discuss your specific needs

Every job is unique. We want to know your exact requirements and draw on our 40+ years of combined experience to deliver precisely what you need.

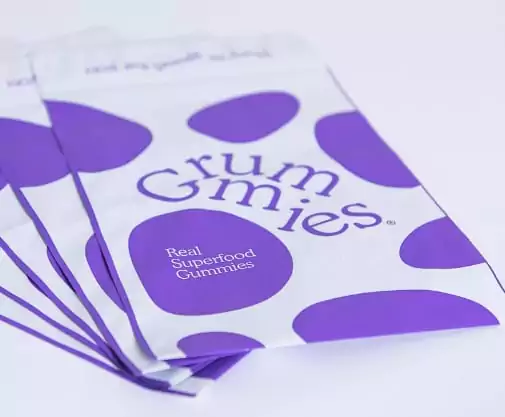

Choose from our wide variety of packaging

We’ve provided packaging for nearly every imaginable product and will create the perfect fit for your products.

Place your order and let us take care of the rest

We know the process inside and out and will make sure you get the results you deserve!

Serving Major Brands Like These Across North America